Nov 13, 2018 By Team YoungWonks *

What is 3D Printing?

3D printing, also known as additive manufacturing, is a transformative technology that allows for the creation of three-dimensional objects from a digital model. This process involves adding material layer by layer, as opposed to traditional subtractive manufacturing, which involves cutting away material from a solid block. The versatility of 3D printing processes makes it applicable in various fields, from healthcare to aerospace. In this comprehensive guide, we will delve into the various aspects of 3D printing, including its processes, technologies, materials, and applications.

The Role of Key Technologies and Companies in 3D Printing

In the realm of 3D printing, companies like 3D Systems play a pivotal role in advancing the field with innovative technologies. Selective Laser Melting (SLM) is one such advanced 3D printing technology that utilizes a high-powered laser to fuse metal powders into solid parts. This technique, also known as laser melting, allows for the creation of complex and durable metal components. For instance, the hull of a spacecraft or high-performance automotive parts can be precisely manufactured using SLM due to its ability to produce strong and lightweight structures. As a leader in the industry, 3D Systems has developed cutting-edge solutions that leverage SLM to meet the demanding requirements of aerospace, automotive, and other high-tech industries.

How Does 3D Printing Work?

The basic principle behind 3D printing involves constructing three-dimensional objects by adding material layer by layer. Here's how printers work:

- Design Creation: A 3D model is designed using computer-aided design (CAD) software. This model is then converted into a format like STL (stereolithography) that the 3D printer can interpret.

- Preparation: The model is sliced into thin layers using slicing software. This cross-section data guides the printer on how to deposit each layer of material.

- Printing: The 3D printer deposits material according to the sliced model. The material could be a filament, resin, or powder, depending on the printing method used. The printer works by precisely controlling the layer height and applying the material in thin layers. During printing, the printer's print head deposits material according to the sliced model. The material is applied in thin layers, and each layer fuses with the one below it.

- Post-Processing: After printing, additional steps may be required, such as cleaning, curing, or adding support structures to achieve the desired surface finish and functionality.

What are the Different 3D Printing Technologies?

3D printing technologies vary based on the method used to build up layers of material. Here are some prominent techniques:

- Fused Deposition Modeling (FDM): Also known as Fused Filament Fabrication (FFF), this method involves extruding thermoplastic filaments through a heated nozzle. The material is deposited layer by layer to build up the object. This is one of the most common 3D printing processes used by hobbyists and professionals alike.

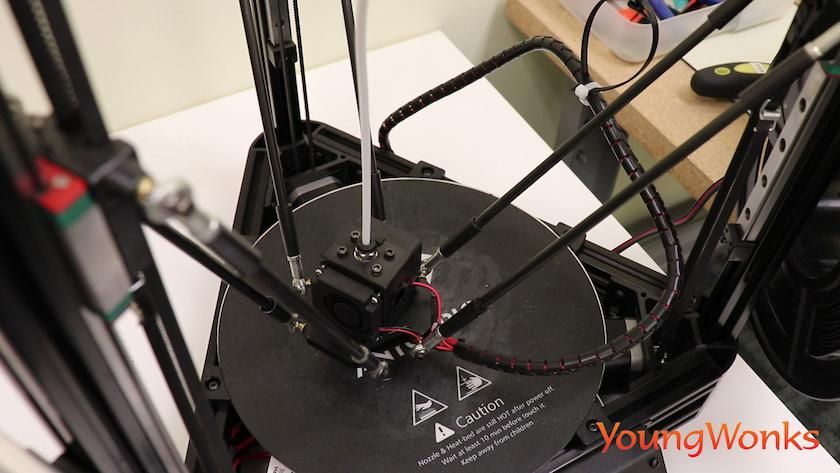

A popular 3D printer today is the Delta 3D printer (shown below); it is called so due to its delta-shaped arms which make the printer’s extruder move and that’s how it prints. This is a type of FDM (Fused Deposition Modeling) printer.

Just like in the regular printer, these Delta 3D printers have their printheads that print layers on top of another. Except here the ink is replaced by a filament as the former doesn’t have the kind of thickness needed to create a 3D object. The filaments can be made of plastic; these filaments are called ABS (Acrylonitrile Butadiene Styrene). There are also corn/ plant-based filaments which are called PLA (Polylactic acid). Both PLA and ABS are thermoplastics. While ABS is more rigid and is found on Lego bricks, PLA is biodegradable and less toxic.

Now to run a 3D printer, the filament goes through the tube and is fed to the extruder. This extruder then passes the right amount of filament needed to the hot end where this filament gets heated up and melts. Then this molten filament passes through the nozzle which ensures that the filament is being poured out in layers in a fashion that will help us achieve the shape of the 3d object we are aiming to create.

Another kind of printer commonly used today is the Cartesian type 3D printer.

These are also FDM printers as they too release the molten filament and print the object in a layer-by-layer manner. Both Cartesian and Delta type printers are classified under FDM printers because they print using plastic filaments that melt and pour out in the form of vertical layers. However, the extruder movements in the Cartesian type printers are different from those in the Delta type printers.

In fact, these printers are called Cartesian because they move along the Cartesian plane (like the one from math class). In these printers, movements occur along the X, Y, and Z axis rods/ coordinates. In other words, in Cartesian printers, we have printheads going left and right, front and back while the print bed (the surface of the 3D printer where a print head lays down the materials that make up a 3D print) goes up and down. In Delta type printers, the print bed is fixed and only the extruder moves. Moreover, instead of the XYZ rods, delta printers have three arms - attached to three vertical posts arranged in a triangle - supporting the extruder.

In addition to the above mentioned differences, Cartesian type 3D printers are said to be more precise when compared to Delta type printers. However, the former are not meant for speed. Delta type printers are the opposite; they may not be as accurate in terms of shape and / size of the object, but they are rather fast.

Among the Cartesian printers we also have enclosed printers. Most printers today are not enclosed; but enclosed printers are recommended as they have a carbon fiber filter that keeps out the fumes, make these printers safer especially for them to be used in a regular room/ non-industrial setup.

- Stereolithography (SLA): SLA uses a laser to cure liquid photopolymers into solid layers. This technology is known for its high resolution and smooth surface finish, often used for detailed prototypes and dental applications.

- Selective Laser Sintering (SLS): SLS involves using a laser to fuse powdered material, such as nylon or metal powder, into solid parts. This method is used for producing functional parts and is a popular choice in the aerospace and automotive industries.

- Digital Light Processing (DLP): Similar to SLA, DLP uses ultraviolet light to cure liquid resin. However, it projects an entire layer at once, which can speed up the printing process compared to SLA.

- Direct Metal Laser Sintering (DMLS): DMLS uses a laser to melt metal powder, creating dense and durable metal parts. This technology is used for producing high-strength components in aerospace and automotive industries.

- Direct Energy Deposition (DED): This technique uses focused energy sources like lasers or electron beams to melt and deposit material, often used for repairing or adding features to existing components.

What Materials Can Be Used in 3D Printing?

3D printing materials are diverse and can be categorized as follows:

- Polymers: Thermoplastics like PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) are commonly used in FDM printing. These materials are printable and offer various mechanical properties.

- Resins: Photopolymers used in SLA and DLP printing are known for their high resolution and smooth finishes. Liquid resin is cured using ultraviolet (UV) light to form solid objects.

- Metals: Metal powders used in SLS, DMLS, and Direct Metal Laser Sintering (DMLS) are used to produce durable metal parts. These materials are suitable for high-strength applications in aerospace and automotive sectors.

- Ceramics: Ceramic materials are used for high-temperature applications and aesthetic objects. They can be printed using methods such as binder jetting.

- Composites: Materials like carbon fiber-infused filaments combine polymers with reinforcing materials to enhance mechanical properties.

Overview of 3D Printing Processes

3D printing encompasses a variety of processes, each suited to different materials and applications. Below are some of the most widely used 3D printing techniques:

Powder Bed Fusion (PBF): Powder Bed Fusion is a process that uses a laser or electron beam to melt and fuse powdered material, layer by layer, to create solid objects. It is ideal for creating complex and highly durable parts. Common methods include:

- Selective Laser Sintering (SLS)

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Melting (EBM)

Material Extrusion: Material Extrusion involves heating a thermoplastic filament and extruding it through a print head, depositing it layer by layer. It is one of the most common and accessible 3D printing methods, frequently used in Fused Deposition Modeling (FDM) or Fused Filament Fabrication (FFF). This process is popular for its simplicity and low cost.

CNC Machining: CNC (Computer Numerical Control) machining is a subtractive manufacturing process where material is removed from a solid block to form the desired shape. It differs from 3D printing’s additive nature and is often used for creating precise and intricate parts from various materials such as metals and plastics.

Inkjet Printing in 3D Printing : Inkjet printing technology is utilized in Material Jetting processes, where droplets of material, such as photopolymers, are jetted onto a build platform and cured layer by layer. This technique enables high-resolution and multi-material prints, often producing detailed and colorful objects.

Material Jetting : Material Jetting is a precise 3D printing process where droplets of photopolymer or other materials are selectively deposited onto a build platform and cured using ultraviolet (UV) light. This method allows for multi-material and multi-color printing, making it ideal for creating highly detailed, high-resolution parts, such as prototypes and medical models.

Vat Photopolymerization: Vat Photopolymerization involves using a light source (laser or projector) to cure liquid resin in a vat, turning it into solid layers. In this process, UV light is often used to cure the photopolymer resin, turning the liquid into a hardened object layer by layer. The two main methods are:

- Stereolithography (SLA)

- Digital Light Processing (DLP)

Binder Jetting: Binder Jetting is a process where a liquid binder is selectively deposited onto a powder bed. The binder adheres to the powder particles, building the object layer by layer. Once completed, the object is typically sintered in a furnace. This method is versatile and works with metals, ceramics, and even food-grade materials.

Direct Energy Deposition (DED): Direct Energy Deposition uses a focused energy source, like a laser or electron beam, to melt and deposit material onto a surface. It’s often used for repairing existing parts or adding material to existing objects and works well with metals and alloys.

Can 3D Printing Be Used for Mass Production?

While traditionally used for prototyping and small-batch production, 3D printing is increasingly being used for mass production. Technologies like SLS and DMLS are utilized in industries like aerospace and automotive for producing parts on demand. However, for high-volume production, traditional methods like injection molding might still be more cost-effective due to faster production speeds.

Can 3D Printers Print Metal?

Yes, 3D printers can print metal parts using technologies such as Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM). These methods involve using lasers or electron beams to melt metal powder, which is then fused into solid parts. Metal 3D printing is valuable in industries requiring high-strength components, such as aerospace and automotive.

Parts of 3D Printer

A 3D printer consists of several key components that work together to create three-dimensional objects. Here are the essential parts of a typical 3D printer:

- Frame: The structural body of the 3D printer that supports all other components. It ensures stability and precision during printing.

- Print Bed: The flat surface on which the object is printed. It may be heated or non-heated, depending on the material being used.

- Extruder: Responsible for feeding the filament or material into the hot end. The extruder typically includes the motor and gears for pushing the filament.

- Hot End: The part where the filament is melted and extruded through a nozzle. It controls the flow of material onto the print bed.

- Nozzle: The tip of the hot end, where the melted filament is deposited layer by layer. Different nozzles vary in size and material, affecting the precision of the print.

- Stepper Motors: Motors that control the movement of the printer along the X, Y, and Z axes. They ensure precise positioning of the print head and bed.

- Belts and Pulleys: These components work with the stepper motors to move the print head or bed along the axes with precision.

- Lead Screws and Rods: Lead screws, typically found in Z-axis movement, help ensure precise vertical motion. Smooth rods guide the movement along the axes.

- Endstops/Sensors: These are used to detect the position of the print head and print bed. They help calibrate the printer and prevent the print head from going beyond its limits.

- Cooling Fans: These fans cool the filament as it is extruded to solidify the layers and prevent warping or deformation.

- Power Supply Unit (PSU): Provides the necessary power to operate the printer, heating elements, and motors.

- Control Board (Motherboard): The brain of the 3D printer, it controls all operations, including movements, heating, and communication with the user interface.

- LCD Screen/Control Interface: A user interface that allows for input and control of the printer’s settings and operation, including print initiation, temperature control, and more.

- Filament Spool Holder: Holds the spool of filament (material used for printing) and ensures a smooth feed into the extruder.

- Power Switch: Turns the 3D printer on and off.

These parts work together to enable the 3D printing process, where material is added layer by layer to create objects.

What are the Benefits of 3D Printing Over Traditional Manufacturing Methods?

3D printing offers several advantages compared to traditional manufacturing methods:

- Complex Geometries: 3D printing allows for the creation of intricate and complex designs that are challenging to achieve with traditional methods.

- Customization: It enables the production of personalized items, such as custom prosthetics tailored to individual needs.

- Reduced Waste: The additive nature of 3D printing minimizes material waste compared to subtractive manufacturing.

- Rapid Prototyping: It accelerates the product development process by allowing quick iterations and modifications.

- On-Demand Production: 3D printing supports on-demand production of spare parts and components, reducing lead times and inventory costs.

How Much Does a 3D Printer Cost?

The cost of a 3D printer varies depending on its technology, size, and features:

- Entry-Level Printers: Basic FDM or Fused Filament Fabrication (FFF) printers can cost between $200 and $500.

- Mid-Range Printers: More advanced FDM or resin printers can range from $500 to $2,000.

- Professional Printers: Industrial-grade printers for advanced applications, such as SLS or DMLS machines, can cost tens of thousands to several million dollars.

Conclusion

3D printing is a game-changing technology that has revolutionized the way we design and manufacture objects. From various 3D printing processes and materials to applications in healthcare and aerospace, its impact is far-reaching. Whether you're a hobbyist exploring 3D printers or a professional leveraging additive manufacturing for production, understanding the different technologies, materials, and benefits can help you harness the full potential of 3D printing. From its core printing methods and materials to specific applications in healthcare and aerospace, understanding the different aspects of 3D printing can help you make informed decisions and leverage its potential. As the technology continues to evolve, it promises to bring even more innovations and efficiencies to the world of manufacturing technologies. As the 3D printing industry continues to evolve, it promises even greater advancements in manufacturing technologies, offering new possibilities for innovation and efficiency in creating three-dimensional objects.

Here's a video on 3D printing:

Exploring the World of 3D Printing with YoungWonks

3D Printing is revolutionizing how we create, innovate, and think about manufacturing, transforming ideas into tangible objects with just the click of a button. At YoungWonks, we recognize the importance of integrating cutting-edge technologies like 3D printing into our curriculum to inspire the next generation of inventors and innovators. Our Coding Classes for Kids provide a comprehensive introduction to the foundational skills needed in today's tech-driven world. For those interested in going a step further, our Python Coding Classes for Kids deepen students' understanding of programming, which is crucial for designing 3D models and controlling 3D printers. Additionally, our Raspberry Pi, Arduino and Game Development Coding Classes offer hands-on experiences that complement the 3D printing process, allowing students to see their code come to life in three dimensions. Through these classes, YoungWonks empowers students to not just be consumers of technology, but creators and innovators in the 3D printing space.

*Contributors: Written by Vidya Prabhu; Edited by : Disha N ;Lead image by: Leonel Cruz