Nov 26, 2020 By Team YoungWonks *

What is an actuator? You may have often heard those working with hardware or electronics talk about valves and actuators. And while our last blog talked about valves, this one is about actuators, often used with valves. So this blog shall share a simple introduction to the actuator; we shall also look at the different types of actuators being used today.

What is an Actuator?

Actuators are mechanical or electro-mechanical devices that, upon being operated electrically, manually, or by various fluids, allow controlled and sometimes limited movements or positioning. They refer to that component of a machine that helps carry out the moving and controlling of a mechanism or system; take for instance opening a valve. To put it simply, they can be called movers.

Actuators basically need a control signal and a source of energy. Upon receiving a control signal, the actuator uses energy from the source to bring about a mechanical motion. The control system can be a human, a fixed mechanical or electronic system, or even software-based, say a printer driver, or a robot control system.

Examples of actuators include electric motors, stepper motors, electroactive polymers, screw jacks, servomechanism, solenoids and hydraulic cylinders.

Types of Actuators

Actuator types also vary depending on motions, power configurations, styles and sizes depending on the application.

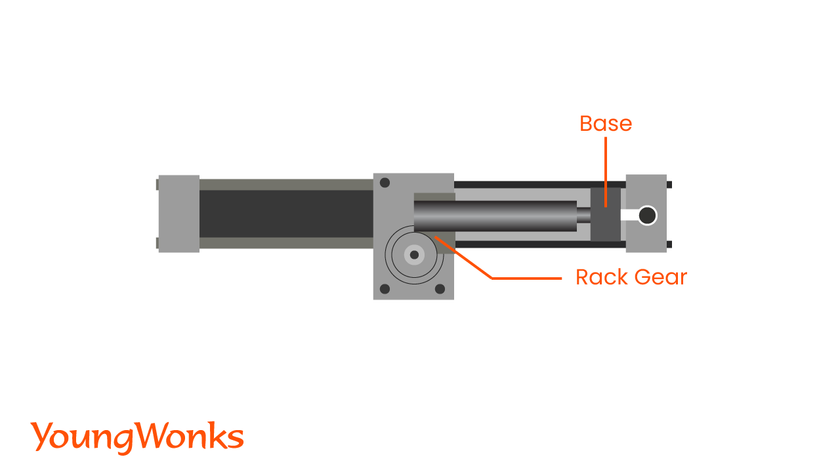

a. Mechanical actuators

Mechanical actuators create movement by converting one kind of motion, such as rotary motion, into another kind, such as linear motion. Say for instance, a rack and a pinion. Another example is that of a chain block hoisting weight where the mechanical motion of the chain is used to lift a load.The functioning of mechanical actuators relies on the combinations of their structural components, such as gears and rails, or pulleys and chains. High reliability, simplicity of utilisation, easier maintenance and greater precision of positioning are some of the advantages. They can be categorised into hydraulic, pneumatic and electric actuators.

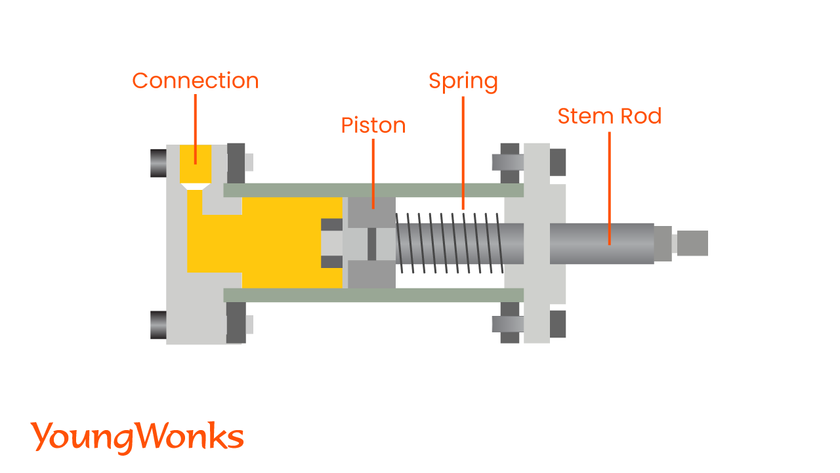

b. Hydraulic actuators

Hydraulic actuators have a cylinder or fluid motor that uses hydraulic power to generate mechanical motion, which in turn leads to linear, rotatory or oscillatory motion. Given the fact that liquids are nearly impossible to compress, a hydraulic actuator can exert a large force. When the fluid enters the lower chamber of the actuator’s hydraulic cylinder, pressure inside increases and exerts a force on the bottom of the piston, also inside the cylinder. The pressure causes the sliding piston to move in a direction opposite to the force caused by the spring in the upper chamber, making the piston move upward and opening the valve. The downside with these actuators is the need for many complementary parts and possibility of fluid leakage.

c. Pneumatic actuators

Pneumatic actuators convert energy in the form of compressed air into mechanical motion. Here pressurised gas or compressed air enters a chamber thus building up the pressure inside. Once this pressure goes above the required pressure levels in contrast to the atmospheric pressure outside the chamber, it makes the piston or gear move kinetically in a controlled manner, thus leading to a straight or circular mechanical motion. Examples include pneumatic cylinders, air cylinders, and air actuators. Cheaper and often more powerful than other actuators, they can quickly start or stop as no power source has to be stored in reserve for operation. Often used with valves to control the flow of air through the valve, these actuators generate considerable force through relatively small pressure changes.

Examples of maker projects using pneumatic actuators include lifting devices and humanoid robots with arms and limbs, typically used for lifting.

d. Electric Linear actuators

Now let us look at the electrical actuators, those that run on electricity.

Taking off from the two basic motions of linear and rotary, actuators can be classified into these two categories: linear and rotary. Electric linear actuators take electrical energy and turn it into straight line motions, usually for positioning applications, and they have a push and pull function. They convert energy from the power source into linear motion using mechanical transmission, electro-magnetism, or thermal expansion; they are typically used whenever tilting, lifting, pulling and pushing are needed. They are also known for offering precision and smooth motion control; this is why they are used in industrial machinery, in computer peripherals such as disk drives and printers, opening and closing dampers, locking doors and for braking machine motions. They are also used in

3d printers and for controlling valves. Some of them are unpowered and manually operated with a rotating knob or handwheel. Electric linear actuators

e. Electric Rotary actuators

Consisting of motors and output shaft mechanisms with limited rotary travel, electric rotary actuators convert electrical energy into rotary motion. Used in a wide range of industries where positioning is needed, and driven by various motor types, voice coils, these actuators work as per specifications such as the intended application, drive method, number of positions, output configuration, mounting configuration, physical dimensions and electrical characteristics. A common use is for controlling valves such as ball or butterfly valves. Other applications include automation applications where a gate, door or valve needs controlled movement to certain rotational positions.

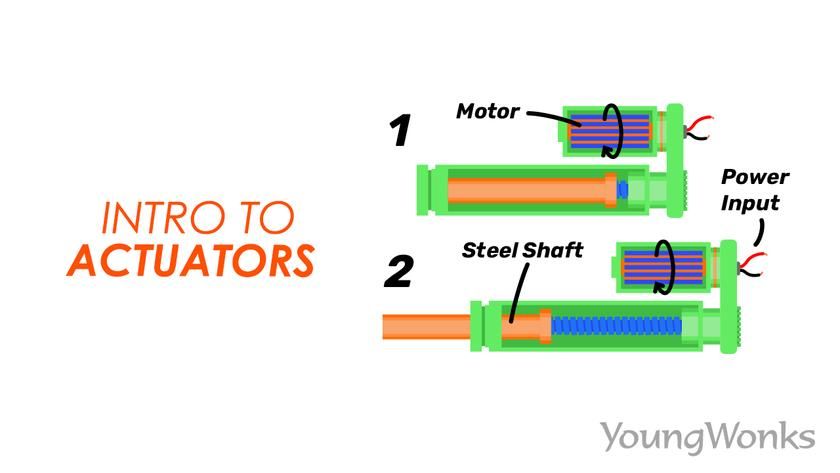

f. Electromechanical actuators

Electromechanical actuators are mechanical actuators where there’s an electric motor in place of the control knob or handle. The rotary motion of the motor leads to linear displacement. The inclined plane concept is what drives most electromechanical actuators; the lead screw’s threads work like a ramp converting the small rotational force by magnifying it over a long distance, thus allowing a big load to be moved over a small distance. While there are many design variations among electromechanical actuators available today, most have the lead screw and the nut incorporated into the motion. The biggest advantages are their greater accuracy in relation to pneumatics, their longer lifecycle and low maintenance effort required. On the other hand, they do not boast the highest speed.

g. Electrohydraulic actuators

Instead of hydraulic systems, electrohydraulic actuators have self-contained actuators functioning solely on electrical power. They are basically used to actuate equipment such as multi-turn valves, or electric-powered construction and excavation equipment. In case of controlling the flow of fluid through a valve, a brake is typically installed above the motor to prevent the fluid pressure from forcing open the valve. The main advantage here is that these actuators help do away with the need for separate hydraulic pumps and tubing, simplifying system architectures and enhancing reliability and safety. Originally developed for the aerospace industry, today they are found in many other industries where hydraulic power is used.

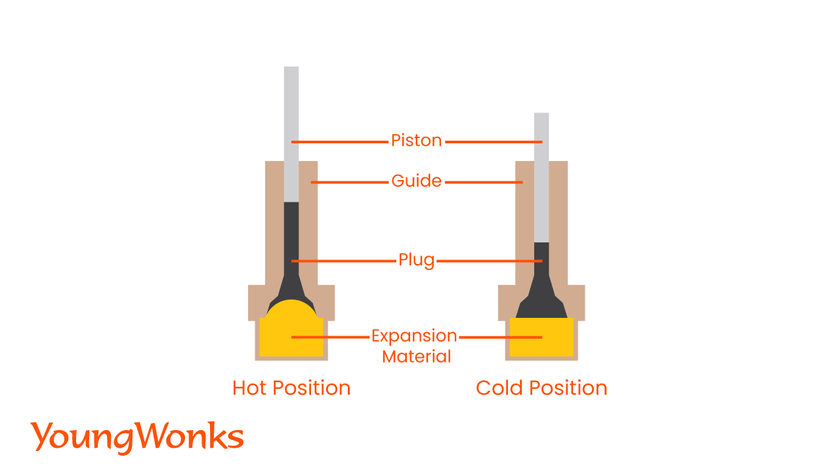

h. Thermal actuators

A thermal actuator is a non-electric motor that generates linear motion in response to temperature changes. Its main components are a piston and a thermal sensitive material. When there is a rise in temperature, the thermal-sensitive materials begin to expand in response, driving the piston out of the actuator. Similarly, upon detecting a drop in the temperature, the thermal-sensitive materials inside contract, making the piston retract. Thus these actuators can be used for carrying out tasks such as releasing latches, working switches and opening or closing valves. They have many applications, particularly in the aerospace, automotive, agricultural and solar industries.

i. Magnetic actuators

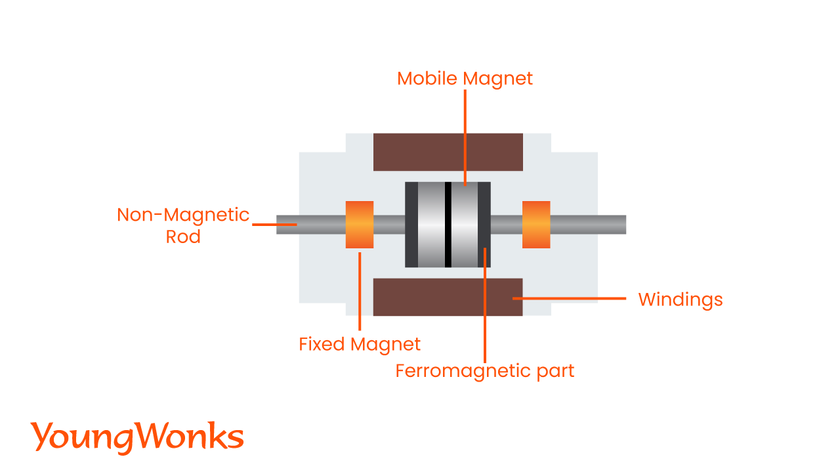

Magnetic actuators are those that use magnetic effects to produce motion of a part in the actuator. They usually come in the following categories: moving coil actuator, moving magnet actuator, moving iron actuator and electromagnetic actuator.

In case of the first kind (moving coil actuator), a mobile coil driven by a current is placed in a static magnetic field, where it is subject to the Lorentz force. This force is proportional to the applied current.

Moving magnet actuators work differently; here mobile permanent magnet is placed between two magnet poles and is switched from one pole to the other using coils. Such actuators can generate high forces but are not easily controlled.

In moving iron actuators, a soft magnetic part placed into a coil system moves in a fashion that keeps the system magnetic energy to a minimum.

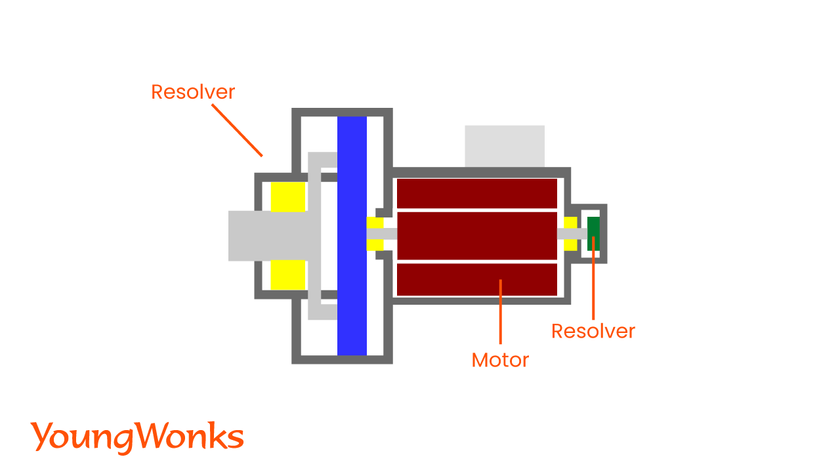

Lastly, electromagnetic actuators are the ones comprising electric motors such as Brushless DC motors (BLDC) and stepper motors. These magnetic actuators are used for various purposes such as valve control, pump and compressor actuation, locking mechanisms,aerospace engineering, vibration generation, fast positioning etc. Advantages include reduced system cost, improved robustness, and reduced control complexity.

Actuators play a pivotal role in the world of robotics and IoT. These components transform an input signal, usually electrical, into motion or some form of mechanical action. From linear to rotary, hydraulic to pneumatic, the variety in types of actuators is vast, each serving a unique purpose in engineering designs. As the world of robotics continues to advance, understanding the intricacies of these actuators becomes increasingly essential. For young enthusiasts eager to dive into the realm of robotics and IoT, starting early can give them a head start. Programs like YoungWonks, which offer coding classes for kids, often use tools like the Raspberry Pi to explore such intriguing topics, providing hands-on experience with actual components, including actuators.

*Contributors: Written by Vidya Prabhu; Lead image by: Leonel Cruz