Apr 14, 2020 By Team YoungWonks *

With COVID-19 pandemic crippling medical facilities worldwide, ventilators have come to be a crucial topic of consideration. Be it the lack of hand sanitisers, hospital beds and now ventilators, many countries are victims of scarcity. It is imperative that this shortage is addressed in a timely and efficient manner.

In this blog, we shall take a look at what is a ventilator, how mechanical ventilation is achieved, types of ventilators, their modes and all the companies or entities that are currently engaged in making or designing ventilators or ventilator augmentation parts.

What is a Ventilator?

A ventilator is a machine that offers mechanical ventilation by moving breathable air into and out of the lungs, to deliver breaths to a patient who is physically unable to breathe, or can’t breathe properly. Ventilators are also called respirators; although today, respirators mainly refers to face masks in contemporary hospital and medical terminology.

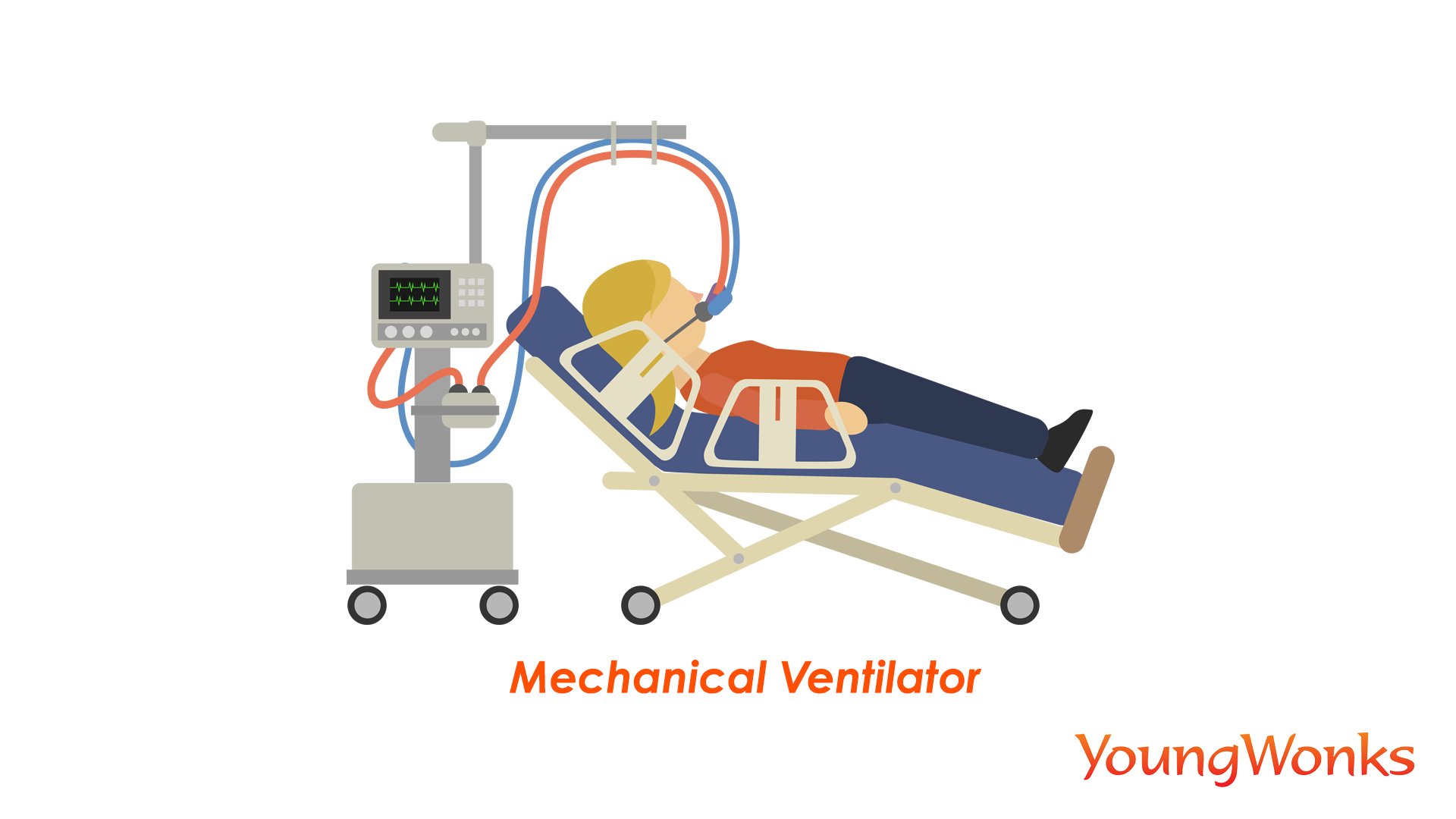

The above image shows the rudimentary way in which manual ventilation takes place.

How Do Ventilators Typically Work?

A ventilator consists of a compressible turbine (in this context, a turbine is a machine where the rotor revolves due to the flow of gas/ air) or air reservoir (like a water reservoir stores water during the rains and provides it during times of drought, air reservoirs address peak demand and help balance the supply of the compressor with the demand of the system), air and oxygen supplies and a set of valves and tubes. The air reservoir compresses many times in a minute to deliver room-air — typically, an air-oxygen mix — to the patient. In case of a turbine, the air is pushed through the ventilator, and the flow valve is used to adjust the pressure depending on the patient’s need. When overpressure (pressure caused by a shock wave over and above normal atmospheric pressure) is released, the patient ends up exhaling due to the elasticity of the lungs and this exhaled air makes its way out through a one-way valve (a valve that allows flow in only one direction) called the patient manifold.

There is manual and mechanical ventilation. Manual ventilators are basically bag valve masks (BVMs) or ambu bags that have to be administered to the patient by a healthcare professional. These are manual resuscitators or self-inflating bags that are used for patients who cannot breathe at all or cannot breathe properly.

Mechanical ventilation, or assisted ventilation, refers to artificial ventilation achieved using mechanical means / instruments.

Types of Mechanical Ventilation

Broadly speaking, mechanical ventilation can be categorised in two:

1) Invasive ventilation: This is when an instrument or device needs to be inserted (referred to as intubation) into the patient’s body (typically, inside the trachea through the mouth).

2) Non-invasive ventilation: This can be achieved without insertion. It is essentially breathing support administered through a face mask, nasal mask, or a helmet.

Top-of-the-line hospital ventilators, the ones that are mainly found in Intensive Care Units, are usually invasive machines that use endotracheal tubes (tubes inserted into the trachea) to support the respiratory system of a severely debilitated patient. The invasive types are generally more robust.

How Mechanical Ventilation is Achieved

There are two main ways in which mechanical ventilation is achieved.

The first is by positive pressure ventilation. Here, a gas mixture is pushed into the lungs through the airways, increasing the pressure in the thoracic cavity (which is where the lungs are), along with the major muscle groups that help in normal breathing. Positive pressure means that the air flows from the ventilator, through the airways and into the lungs, till the breath of the ventilator ceases. Once this happens, there is no more airflow in the airways, and the pressure is zero. This is followed by exhalation where the air is pushed out of the patient’s body in a passive manner, thus completing a breath cycle.

Meanwhile, a negative pressure ventilation system () is one where negative pressure is produced outside the patient’s chest and is transmitted to the interior so as to expand the lungs and allow air to flow in. Such a system basically exposes the surface of the chest wall to subatmospheric pressure during inspiration whereas, and the expiration takes place when the pressure around the chest wall increases and becomes atmospheric or greater than atmospheric pressure. This ventilation system was used during the later stages of the nineteenth century and has now become mostly obsolete.

Ventilator Breaths

There are three types of ventilator breaths that a patient can receive while on a ventilator:

a) Controlled Breath:

A controlled breath delivered by a ventilator is well, completely controlled. A patient does no work at all in this scenario. Generally, a ventilator is not set up in this mode.

b) Assisted Breath:

In this mode, a breath is delivered by the ventilator when it senses that the patient is trying to take a breath. This may be done through the use of a wide array of sensors. Some detect changes in electrical outputs of the diaphragm, or pressure sensors that detect the changes in relative pressure of the airways and use this information to deliver a breath. With this mode, the ventilator takes over only when a patient has initiated the process of inhaling.

c) Supported (Spontaneous) Breath:

Similar to assisted breaths, supported breaths are also triggered in a ventilator upon sensing effort on the patient’s part. But unlike assisted breaths, the point in time when the ventilator detects effort, it does not provide full support for the patient, but some.

Risks Associated with Mechanical Ventilation

While ventilators are life-critical systems intended to save lives, there are several risks that come with their use.

One has to bear in mind that a ventilator aims to help the patient breathe or breathe better but for this to happen, the airflow from the ventilator needs to be in sync with the patient’s breathing, i.e. both inhalation and exhalation. If this is disturbed, it can lead to several complications that can worsen and potentially even lead to the patient’s death.

Potential complications that can arise from the use of mechanical ventilators include the following:

- Pneumothorax: This refers to abnormal collection of air in the space between the lung and the chest wall

- Oxygen toxicity: Where the oxygen levels go beyond normal

- Airway injury/ alveolar damage: Can be caused by high pressure in the ventilator

- Ventilator-associated pneumonia (VAP): This is a type of lung infection that typically attacks those who are on mechanical ventilation breathing machines in hospitals for prolonged periods

- Ventilator-associated tracheobronchitis (VAT): Another hospital-acquired infection seen among patients using mechanical ventilators in Intensive Care Units (ICUs); here there’s inflammation in the bronchial airways and trachea of the patient

- Barotrauma: A well-known complication of positive-pressure mechanical ventilation, barotrauma is physical damage to body tissues caused by a difference in the pressure between a gas space inside, or in contact with, the body, and the engulfing gas or fluid. Initially, the tissues overstretch here and can eventually even rupture

- Ventilator-associated lung injury (VALI): This lung injury is clinically no different from acute lung injury or acute respiratory distress syndrome (ALI/ARDS)

- Diaphragm disuse atrophy: Controlled mechanical ventilation can cause this rapid type of atrophy (wasting away of body organ or tissue) which affects diaphragmatic muscle fibers

- Pneumonia: Mechanical ventilators can interfere with the release of bronchial mucus; this can even lead to pneumonia.

How the overwhelming demand for ventilators is being met in times of COVID-19

Ventilators are complex machines and producing them takes up a lot of time and money. Thus, producing ventilators that are cheap, efficient and ideally easy to build and transport is no small task.

Indeed, the challenge is to build a scalable design that can be conceived at a relatively short notice and can be shipped to the healthcare facilities in the parts of the world where it’s most required.

First, let’s take a look at some ventilator makers already involved in ventilator production. Leading the list is Becton Dickinson; this American medtech company is said to have the largest market share of any company working in ventilator production in 2020. Another big player is Hamilton Medical — a Swiss subsidiary of US biotech company Hamilton — which boasts expertise in the area of intelligent ventilation solutions, some of which are even used in critical care transport vehicles such as rescue helicopters.

Philips is also a name worth mentioning here as the Amsterdam-based electronics company has expanded to make respiratory products including ventilation systems used in hospitals and at home. In addition to mining and gas detection, German tech company Draeger is also into making ventilators for use within intensive and emergency care settings of a hospital, as well as producing devices for anaesthesia, and patient monitoring. Meanwhile, Fisher & Paykel Healthcare is into manufacturing invasive and non-invasive ventilators for adults, as well as humidification and resuscitation for young patients and newborns.

And given how desperately ventilators are needed in various Coronavirus-struck countries across the world, a lot of companies from other sectors have now repurposed manufacturing to meet the overwhelming demand.

For example, Tesla founder Elon Musk has been in talks with Medtronic, an Irish company that works extensively in the US in the field of ventilator production. US car manufacturer Ford teamed up with GE Healthcare to increase production of ventilators (and respirators, masks and gloves).

Aerospace company Airbus has brought together rival manufacturers from a range of industries in a unified national effort to increase the number of ventilators for the UK’s NHS.

Rolls-Royce, Siemens, GKN and Meggitt, Formula 1 team McLaren, aerospace company BAE Systems and Ford are using their facilities to manufacture more ventilators dwelling on designs used by medical device manufacturers Smiths Medical and Penlon.

Hand dryer and vacuum cleaner company Dyson has designed and built a whole new ventilator that it calls the CoVent. Automaker General Motors aka GM has gotten into a contract with the federal government whereby the former shall supply the latter with thousands of ventilators for those suffering from the coronavirus. Ventec Life Systems, a ventilator manufacturer based in Bothell, Washington, has teamed up with GM to ramp up their production; they hope to soon hit their target of 10,000 ventilators per month. Virgin Orbit, the Virgin Group’s satellite launch arm, is working on the design and development of a simple, low-cost and highly scalable bridge ventilator.

In India, the Noida-based AgVa is producing ventilators the same size as a toaster which makes it quite portable. Priced at approximately $2,000, these ventilators cost a fraction of the price of conventional ventilators, which typically cost upwards of $10,000. Another low-priced ventilator is that produced by the Mahindra Group; it has already produced prototypes of ventilators and its engineers claim that each ventilator shall cost less than Rs 7,500 (less than $100).

Educational institutions too are doing their bit. A volunteer team of engineers, physicians and computer scientists at Massachussetts Institute of Technology (MIT) - called MIT E-Vent (for emergency ventilator) - has now come together to reference a project done a decade ago in one of their Medical Device Design classes. In doing so, they are looking to produce a simple, low-cost ventilator (priced at no more than $500), fashioned out of a hand-operated plastic pouch called a bag-valve resuscitator that is typically easily available in hospitals in large quantities.

While it is no doubt commendable that these ventilator and non-ventilator making companies are now rising to the occasion and doing their bit in the fight against COVID-19, we would do well to keep in mind that - as mentioned earlier in this blog - mechanical ventilation comes with its set of risks. Particularly in the case of low-cost ventilators and hand-operated ambu bags, extra precautions may be needed to ensure their smooth functioning.

The Role of Technology in Healthcare: Ventilators During the Coronavirus Outbreak

In the midst of the coronavirus outbreak, technology plays a crucial role in saving lives, with ventilators standing out as essential devices for patient care. At YoungWonks, we recognize the importance of understanding both the technology behind these life-saving machines and the software that powers them. Through our Coding Classes for Kids, we introduce students to the basics of programming that can be fundamental in developing innovative solutions for healthcare. Our Python Coding Classes for Kids explore how software can be used to monitor and control medical devices, including ventilators. Similarly, our Raspberry Pi, Arduino and Game Development Coding Classes encourage students to think creatively about using technology to solve real-world problems, setting the foundation for future innovations in healthcare technology.

*Contributors: Written by Sujit Nair and Vidya Prabhu; Images by Leonel Cruz